Investigation launched into potential gas exposure at Nevada solar plant

A Las Vegas law firm is launching an investigation into allegations of employees’ gas exposure at the Crescent Dunes Solar Energy Project.

Craig Drummond, attorney from Drummond Law Firm in Las Vegas, said he is in the early stages of the investigation into employees’ potential exposure to nitrogen dioxide gas from a hot salt tank at the solar plant near Tonopah.

Drummond was hired by Timothy Stiver, a former mechanical supervisor at Cobra, a Madrid, Spain-based contractor for Crescent Dunes Solar Energy Project. Stiver alleged that he and a group of other workers were hospitalized after inhaling the gas emitted from the hot salt tank.

On Sept. 14, Drummond filed a representation notice and evidence preservation request. The document is asking Cobra and several other contracting and subcontracting companies who work on the plant to preserve all materials related to the hot salt tank at the Crescent Dunes Solar Energy Project and forward them to Drummond Law’s office.

Drummond, a former JAG prosecutor for the Army, said in the document that request is made so that his office is allowed to “immediately” inspect and document the current condition of the tank and related locations before any repairs, changes, or modifications are made.

“We are trying to figure out who’s responsible for what, and what exactly is going on,” Drummond said in an interview.

Stiver, 53, relocated to Tonopah from Florida four years ago, to work on the Crescent Dunes Solar Energy Project.

In late August, he said he had a respiratory failure after working in the unit next to the hot salt tank.

“I woke up at about one o’clock in the morning, had burn all the way down to the middle of my chest, I couldn’t stop coughing,” Stiver said in an interview.

An hour later, he started vomiting.

“I was in a fetal position until 5:30 in the morning,” Stiver said.

After missing a day of work due to his sickness, Stiver started coughing up blood the next morning. Stiver’s wife drove him to a hospital in Reno where he spent the next few days.

“The physician that read my chart told me to expect scar tissue on my lungs, I’ve got a problem with the upper-left lobe of my lung,” Stiver said.

Stiver’s medical records show he had acute chemical pneumonitis and acute respiratory failure with hypoxia. He will remain on medication for the next 90 days.

Doctors told Stiver not to go on the site if nitrogen dioxide, otherwise known as NO2, is present, according to his medical record dated to Sept. 14.

Stiver said his safety director showed up at the hospital and assured doctors that no nitrogen dioxide was at the facility.

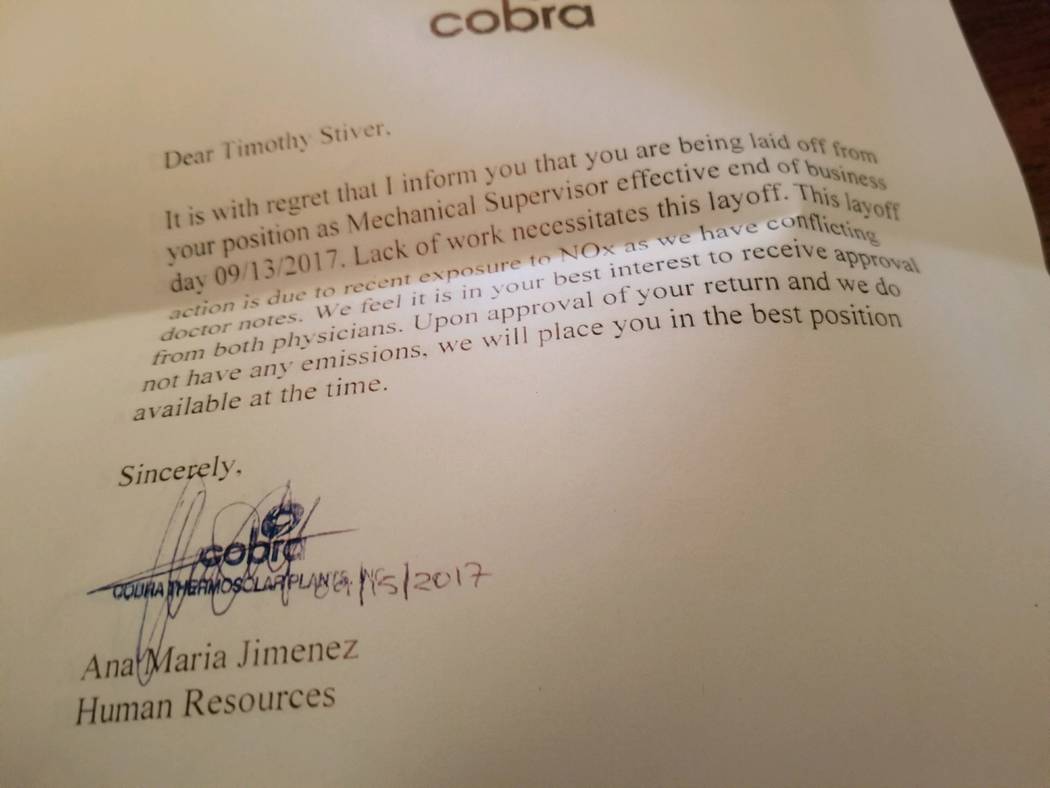

Stiver went back to work but after finding out that the gas was still present, and talking to his employer, he was laid off on Sept. 13.

“Lack of work necessitates this layoff. This layoff action is due to recent exposure to NOx as we have conflicting doctor notes,” the notice said.

Cobra didn’t return a request for comment.

Stiver, who is currently on workers’ compensation, said nitrogen dioxide has been emitting at Crescent Dunes for the past five months, during which about seven other workers had been hospitalized with similar diagnoses. Their symptoms ranged from rashes to second-degree throat burns, headaches and vomiting.

An employee for another contracting company at Crescent Dunes, who declined to identify herself, said that she had experienced throat burns accompanied by a strong headache while she was at work on Aug 23.

“My boss personally drove me to Hawthorne,” the woman said. “I got a breathing treatment, I got on steroids, which messed with my blood sugar because I’m diabetic. … That really tore me up. I couldn’t stay focused, it was miserable. I’ve never felt that way.”

Before she left the emergency room, she said another worker arrived with second-degree burns on his throat.

Mary Grikas, spokeswoman for Santa Monica, California-based SolarReserve, the parent of Crescent Dunes, said the company had no comment on Drummond Law’s filing.

In a separate email, Grikas said that safety is “a top priority” for the Crescent Dunes Solar Energy Project, and the site maintains “strict” procedures to comply with all federal, state and local safety regulations.

“The facility management diligently monitors the working environment to ensure it is safe for staff on site, and OSHA has completed two inspections in the last 30 days and the project was found in compliance with OSHA standards and received no violations,” Grikas said in an email.

Drummond had no further comment but did confirm that his office has been retained by at least one other employee at Crescent Dunes in addition to Stiver.

Documentation

On Sept. 22, Joseph Long, plant manager at PIC Group Inc., another contractor at Crescent Dunes, sent out an email asking workers at the plant not to erase any project documentation associated with the hot salt tank.

“Due to an emerging legal matter affecting a project subcontractor which we may have information relating to we, as the operator at Crescent Dunes, have been instructed to not erase any project documentation associated with the hot salt tank leak,” Long said in an email.

Those materials may include any emails, correspondence, documents, reports, notes, photographs, records, statements, etc. in connection with the molten salt tank and gas issues, according to an email.

“If you have documentation (photos or videos) that were taken for work purposes but are on personal devices please contact me and I will provide a link to the server for them to be uploaded to,” Long said in an email.

Stiver hasn’t filed a lawsuit yet. He said many of the workers who exhibited the symptoms similar to his are afraid to speak publicly about the issue because of potential repercussions from the contracting companies who employ them.

Stiver and the woman said workers at the plant file incident reports whenever the readings detect various levels of nitrogen dioxide in different areas of the plant.

A photo provided by Stiver shows an orange-brown stream of gas coming out of a pipe of the hot salt tank.

“If it’s strong enough, you can smell it. Usually, it dissipates pretty quick, so you can’t see it,” Stiver said. “If you see the cloud, you don’t want to be around it, that’s for sure. Because if it’s that thick, it’s going to put you down.”

The noxious gas cloud travels with the wind in different directions, Stiver said.

Drummond said the question is “was it an unsafe and dangerous working environment then and is it now?”

“Certain employees out there wear monitors and there are monitors that are at certain locations of the plant,” Drummond said.

Grikas said in an email that the facility management has maintained strict monitoring to confirm that any fumes related to the project operations remain well below OSHA standards and industry requirements.

“Independent monitoring has confirmed that the facility is maintaining a safe working environment and remains in full compliance with all applicable regulations. This was also confirmed in the OSHA inspections,” Grikas said in her email.

“Keep in mind that the Crescent Dunes project is an operating utility scale power plant, and there are risks normally related to industrial facilities and projects of this type, including high voltage electrical systems, high temperature fluids and high temperature/pressure steam, high speed rotating equipment, handling of chemicals related to water treatment systems, as well as the use of heavy machinery such as diesel trucks,” Grikas said.

Salt tank issues

Crescent Dunes was recently offline for more than eight months because of a salt leak at the hot salt tank. Stiver questioned whether the hot salt tank was fixed properly, as he said it still emits NO2 gas, after the leaked salt mixed with the soil.

Stiver said Cobra has bought seven respirators for 80 people. Those employees who work in the solar field don’t have monitors that would detect levels of nitrogen dioxide, Stiver said.

When the salt was leaking out of the tank, Stiver said employees at the plant bagged the salt and put it in front of the plant.

“As they were heating up the tank, they kept having more leak-outs. In the course of five-six months, they’ve been bagging it up and stacking it,” Stiver said.

The plant’s workers also redirected the exhaust that was emitting the smoke into the solar field, Stiver said, but he and the woman claimed the wind still blows the wind back toward the plant.

‘Groundbreaking’ facility

The Crescent Dunes project was backed by a $737 million federal loan guarantee from the U.S. Department of Energy in 2011.

Officials at SolarReserve have touted the solar thermal energy storage technology used in the plant as “groundbreaking,” as SolarReserve is the only supplier in the U.S. that uses technology concentrating solar power with molten salt energy storage.

Grikas said that the output for the 110-megawatt Crescent Dunes “varies daily, hourly and minutely,” depending on a lot of factors including maintenance activities, with weather and the amount of sun being the biggest factors.

The hot salt tank leak was fully repaired and is performing “properly” with no additional leaks, she said.

Stiver gave a different account.

“Now what they are doing is they are going to take and do a temporary patch on this tank again to try to make it run to limp through, so they could bring the tank temperature up, make some power, make everybody happy, and then they will probably repair it again later or some other time,” he said.

Stiver said he has reached out to officials including the Nevada Attorney General’s Office, governor’s office and Nevada’s Occupational Safety and Health Administration in Reno to no avail.

“Meanwhile, how many more people are going to get sick, how many more people are going to get affected by this stuff?” Stiver asked.

Contact reporter Daria Sokolova at dsokolova@pvtimes.com. On Twitter: @dariasokolova77